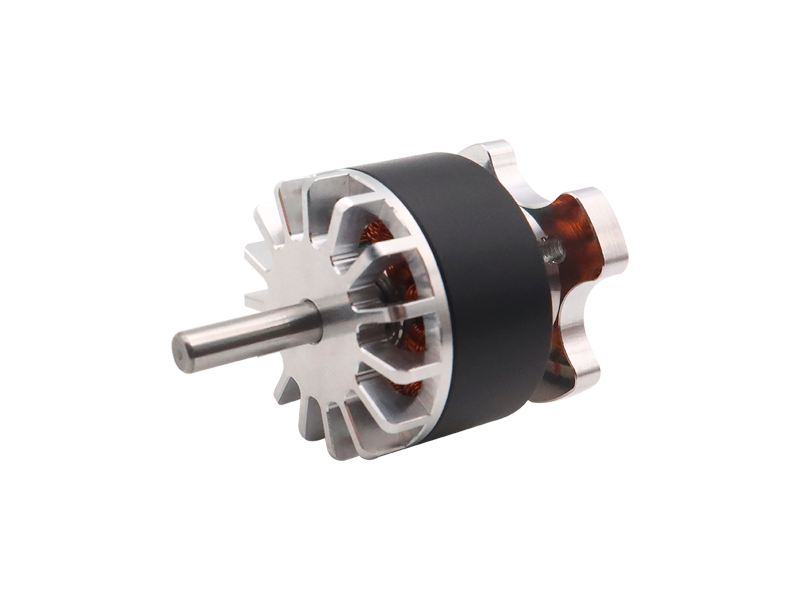

Advantages and disadvantages of brushless and

brushed motors.

advantage:

1. Low running sound

This will be the direction in which our civilized society will inevitably move forward. Any other tool requires reducing noise to protect our sound environment. The most crucial thing now is to use it in quiet places such as hospitals, banks, airports, schools, and so on.

2. No sparks

In some situations, one can show off their skills in areas that are flammable and explosive.

3. Long lifespan

Because it replaces the commutator and carbon brush with a controller, which is several times or even more than ten times that of a brushed motor. The lifespan of carbon brushes has a certain limit, for example, after a thousand hours, the brushes will wear out completely and can only be replaced, but the motor can be replaced.

4. High speed

Because magnetic field induction is used, there is no substantial contact speed that can be achieved faster.

Disadvantages:

1. High cost

The cost of the controller has increased by at least a hundred yuan, taking micro motors as an example. The cost of the original commutator and carbon brush was much lower.

2. If the environment used is in a high magnetic field or has been in contact with or in close proximity to a high magnetic field, the motor will lose its function

Because the rotor components of the motor are made of magnets, they are magnetized to become magnetic. When subjected to high magnetic fields, the magnetic field of the rotor will be changed or some of the magnetic components will be removed, and the motor will not function properly.

Advantages and disadvantages of brushed motors

advantage:

1. Simple structure

The brushed motor mechanism is simple, easy to produce and process, convenient to maintain, and easy to control; DC motors also have fast response, large starting torque, and the ability to provide rated torque from zero speed to rated speed.

2. Smooth operation, good starting and braking effects

Brushed motors are regulated by voltage and speed, so they start and brake smoothly, and also run smoothly at constant speed. Brushless motors are usually controlled by digital frequency conversion, which first converts AC to DC and then DC to AC, and controls the speed through frequency changes. Therefore, brushless motors operate unstably and vibrate greatly during starting and braking, and only stabilize when the speed is constant.

3. High control accuracy

Brushed motors are usually used together with gearboxes and decoders to increase the output power of the motor and improve control accuracy. The control accuracy can reach 0.01 millimeters, allowing moving parts to stop almost anywhere they want. All precision machine tools use DC motors to control accuracy.

Disadvantages:

1. There is friction between the electric brush and the commutator, resulting in reduced efficiency, increased noise, and easy heating. The lifespan of brushed motors is several times shorter than that of brushless motors.

2. Maintenance is troublesome and requires constant replacement of brushes.

3. Due to high resistance, low efficiency, and low output power.

4. Friction between electric brushes and commutators can cause sparks and significant interference.

Extended Information

Let's talk about the differences between brushed motors and brushless motors from several aspects:

1. Scope of application:

Brushless motor equipment can be used in the dairy industry, brewing industry, meat processing industry, soy processing industry, beverage processing industry, pastry processing industry, pharmaceutical industry, electronic precision factories, and other higher demand dust-free workshops. For example, Dior's brushless motor (DIHOUR) hand dryer is widely used in factories.

Carbon brush motor: It can only be used in areas with low requirements such as various bathrooms, and cannot be used in cleanrooms and explosion-proof workshops.

2. Service life:

Brushless motor: can work continuously for about 20000 hours, with a conventional service life of 7-10 years.

Carbon brush motor: can work continuously for about 5000 hours, with a conventional service life of 2-3 years.

3. Usage effect:

Brushless motor: Running at a high speed of 90-95m/s, the actual effect can achieve a dry hand time of 5-7 seconds.

Carbon brush motor: The operating speed and hand drying time are much lower than brushless motors.

4. In terms of energy conservation:

Relatively speaking, the power consumption of brushless motors is only one-third of that of carbon brushes.

5. In terms of future maintenance

After the carbon brush motor wears out, not only is the carbon brush replaced, but also the accessories around the motor such as the rotating teeth are replaced, which is much more expensive. The most important thing is that the overall functionality will be affected.