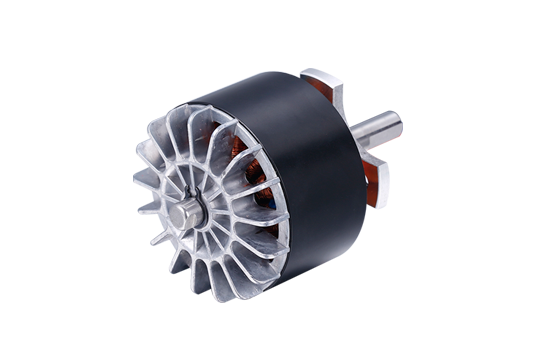

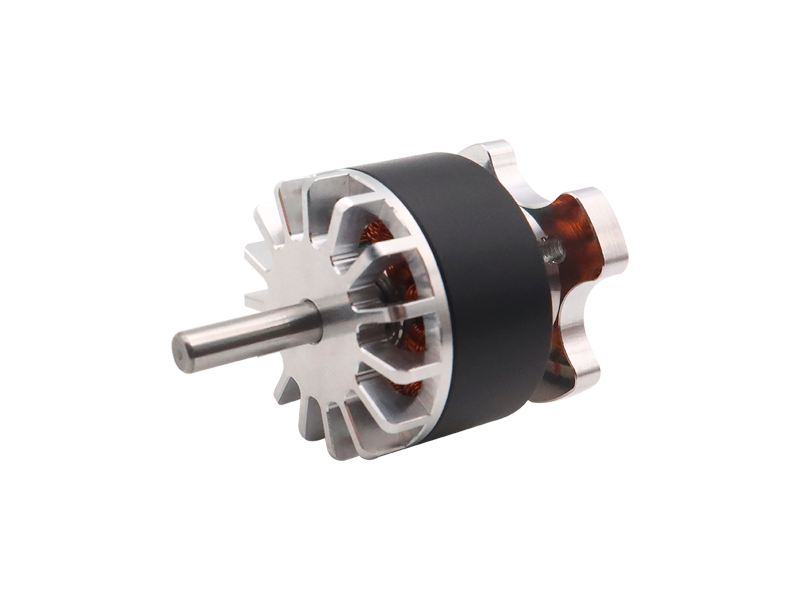

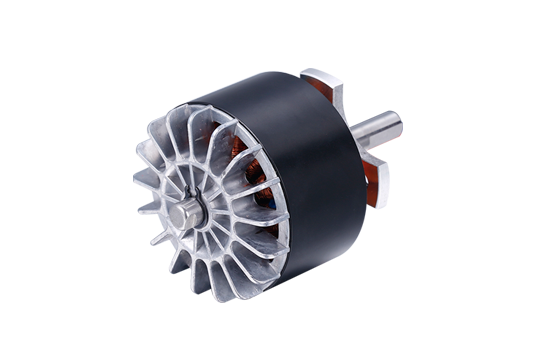

How to control brushless motors and perform basic maintenance?

Brushless motors have three control modes: square wave control, sine wave control, and FOC control. Sometimes, the controller may experience motor no-load or current and voltage adjustment, which requires maintenance according to specific situations. Below is a detailed introduction.

Control method of brushless motor

Square wave control

Square wave control uses Hall sensors or sensorless estimation algorithms to obtain the position of the motor rotor, and then performs 6 reversals (every 60 °) within a 360 ° electrical cycle based on the rotor position. Each reversing position motor outputs a specific direction of force, so it can be said that the position accuracy of square wave control is 60 ° electrical. Due to the fact that the phase current waveform of the motor is close to a square wave under this control method, it is called square wave control. The advantages are simple control algorithms, low hardware costs, and the ability to achieve high motor speeds using controllers with ordinary performance; The disadvantages are large torque fluctuations, presence of certain current noise, and inability to achieve maximum efficiency. Square wave control is suitable for situations where the requirements for motor rotation performance are not high.

Sine wave control

The sine wave control method uses SVPWM waves, which output a 3-phase sine wave voltage, and the corresponding current is also a sine wave current. This method does not have the concept of square wave controlled commutation, or assumes that an infinite number of reversals are performed within one electrical cycle. Obviously, compared to square wave control, sine wave control has smaller torque fluctuations and fewer current harmonics, making it feel more "delicate" to control. However, the performance requirements for the controller are slightly higher than square wave control, and the motor efficiency cannot be maximized.

FOC Control

Sine wave control achieves voltage vector control and indirectly controls the magnitude of current, but cannot control the direction of current. The FOC control method can be considered as an upgraded version of sine wave control, which realizes the control of current vector, that is, the vector control of motor stator magnetic field.

Basic maintenance of brushless motor controller

The motor is unloaded, and some motors are around 1.8A. When the control board is not working, the signal light on the board should first flash at a rate of seconds per second. If the signal light does not flash without adding a switch signal, the following should be checked:

Whether the 5V voltage is normal, whether there is a short circuit in the external plug when it is abnormal, and whether there is a tin short circuit on the board;

Is the voltage of the second pin of the microcontroller 5V;

Does the quartz crystal work;

Does the quartz crystal work;

Is the signal light damaged.

Controller current and voltage adjustment

Current adjustment: Adjust the length of the constantan (the new program can adjust the resistance (R6) of pin 6 of LM358 to ground, with a value range of 2K to 3.3K, and adjust it to the required operating current. The old program has a good operating effect from 26A to 35A for 500W, and the new program has a good effect from 22A to 28A. )

Voltage adjustment: The undervoltage sampling circuit consists of two voltage divider resistors for a 48V or 36V power supply to ground. Usually, adjusting the resistor (Ra) connected to the power supply can adjust the undervoltage point. Since the resistor connected to ground is usually 1.2K, the undervoltage value and resistance value can be calculated according to the following formula: Ra=(1.2xv-1.2x3)/3 Example: When using a 48V battery voltage and the undervoltage V value is 40.5, Ra=(1.2x40.5-1.2x3)/3------- → Ra=15K Note: 1.2 is the resistor connected to ground. In the equation, 3 represents the undervoltage AD value processed by the microcontroller unit. When the undervoltage value needs to be adjusted between 40.5V and 42V, the undervoltage corresponds to 41.04V, 41.65V, 41.75V, 41.86V, and 42V when the full load 1.2K resistor is connected to 82K, 39K, 36K, 33K, and 30K.