Application of Brushless Motors in Logistics Sorting.

The intelligent logistics automatic sorting machine drives the logistics sorting motor to sort items on both sides according to pre-set computer instructions, saving space; And deliver the sorted items to the designated mechanical location through a conveyor belt. With the development of laser scanning, barcode and computer control technology, the use of automatic sorting machines in logistics is becoming increasingly common. E-commerce, express delivery, clothing, books, medicine, and tobacco are developing rapidly, and super large sorting centers that process millions of items per package per day are emerging. The surface of the balance wheel sorting motor usually adopts an outer rotor brushless motor wrapped with rubber (or polyurethane) structure, which effectively avoids damage to the surface of the conveyed items when turning for sorting. With its advantages of high efficiency, high accuracy, and low damage rate, it gradually replaces traditional manual sorting.

The intelligent sorting system determines which sorting gate the goods should enter through barcode scanning, color code scanning, keyboard input, weight detection, voice recognition, height detection, and shape recognition. By introducing automated equipment, sorting operations have basically achieved the advantages of unmanned operation, low error rate, and high sorting efficiency.

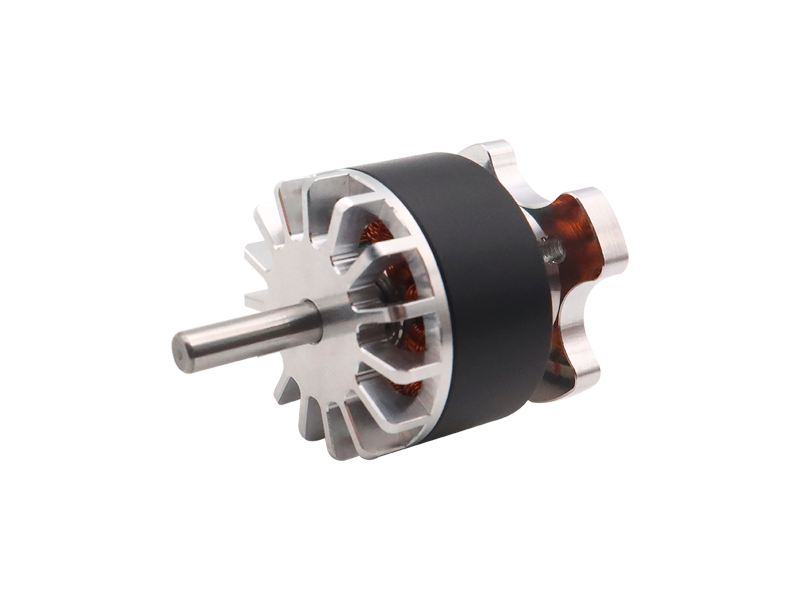

The full series of sorting motors designed and produced by Shenzhen Yateng Motor Co., Ltd. (specific models refer to the following figure) have been widely used in logistics sorting systems, playing a key role as logistics sorting motors. The main characteristics are as follows:

1. Integrated logistics sorting motor and driver, small in size, saves installation space, and is easy to install;

2. Simplify the connection between logistics sorting motors and drivers, with high reliability, high waterproofness, and low noise;

3. Wide speed range (1800RPM~9500RPM), precise control, and rapid response;

4. High torque, high transmission efficiency, long lifespan, capable of continuous operation for over 10000 hours

5. Flexible design changes, with the option to choose motors of different sizes. The motor packaging can be made of polyurethane CPU/TPU, which has good wear resistance;

6. In depth customization according to customer requirements, including motor performance, external structure, installation interfaces, functions, etc.